resin 3d printer vs filamentrobotic rideable goat

While the settings can be optimized to reduce issues such as stringing, it is nearly impossible to completely eliminate the quality defects.The resin miniature was printed using Siraya Tech Simple Smoky Black with the universal resin default of 0.05 mm layer height. 4D Filtration may receive commissions for referral links. These constructions will enable coral to grow upon them, which is considered as an accomplishment in helping tormented coral reefs from the various threats they face around the world. Resin printers are able to capture very fine details because the resolution of each layer is defined by the size of pixels on the LCD screen, which are typically ~70 microns for consumer DLP 3D printers. You can replace most individual components of the hot end, or replace the entire assembly if time is more of a factor than cost.

This allows you to print a model with extremely fine detail, far more than a standard filament printer can produce, and the result tends to need far less post-processing work to give you a finished product. How To Celebrate Easter With 3D Printing To find properties of filaments, visit our FDM Properties Table. Swapping colors is also simple, and is just a matter of pulling out the old filament and inserting the new material.

The extruder gear, which contacts the filament and pushes it into the hot end can wear over time, and the spring loaded extruder mechanism can crack if your 3D printer is using an extruder made of plastic. All other trademarks and registered trademarks are the sole property of their respective owners. You will also have to wash the print and further cure it after it has been printed to get the full effect. A string of plastic called a filament is melted through a hot end and deposited on the build plate. Once assembled, leveling the print bed can take a bit of trial and error. Follow us and you will always be updated on the news! When considering which of these types of 3D printers to purchase, youll first need to think about what types of objects you are planning to make.

This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. Here are some 3D printed objects that caught our eye. In these cases, resin can often be substantially faster for cases where you need a lot of parts. FDM printing is used far and wide in modeling and for producing larger parts like cosplay armor and helmets. All Rights Reserved. Once you access the LCD, you can plug the new LCD in with no soldering or wire splicing required. Printing filament parts is more manageable since you only need to purchase a magnet-built to extract the finished piece. You might be asking: is filament or resin better for 3D printing? The downside is that they tend to have smaller build plates than filament (FDM) printers, so you can't make large pieces on them. For comparison, each layer on a resin printer is typically 25 - 50 microns thick, while filament printer layers are typically 100 - 300 microns thick. Then, you need to cure it under UV light. Because of this, budget resin 3D printers are priced in the same range as entry level filament 3D printers. last updated 31 May 22, Windows Central's expert reviewers spend hours testing and comparing products and services so you can choose the best for you. With typical settings, filament printers can produce single objects much faster. Most budget FDM printers are near the build volume of 220x220x250 mm. Please refresh the page and try again. Swapping colors requires carefully pouring the resin from the vat into the resin container, then cleaning the vat (or purchasing dedicated vats for each material).  With Easter just around the corner, it is the perfect way to spruce up your room, house, classroom or shop with Easter or spring themed 3D printed decorations. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out. Filtration can be used as mitigation and a secondary defense. For filament printers, parts typically use a meshed infill pattern, which saves material. 02/05/2022 Most filament printers require some assembly, but the difficulty can vary. The Prusa Mini is the cheapest printer that can use these filaments without major modifications. James built his first PC when he was 13 and has never looked back.

With Easter just around the corner, it is the perfect way to spruce up your room, house, classroom or shop with Easter or spring themed 3D printed decorations. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out. Filtration can be used as mitigation and a secondary defense. For filament printers, parts typically use a meshed infill pattern, which saves material. 02/05/2022 Most filament printers require some assembly, but the difficulty can vary. The Prusa Mini is the cheapest printer that can use these filaments without major modifications. James built his first PC when he was 13 and has never looked back.

The Voron is a project printer that will cost ~$1,000, and its pre-assembled version, the Troodon, will run $1,500+. Once the layer is completed, the nozzle is moved up, and the next layer is built on top of the last one, until a full 3D part is created. Filament printers have moving parts in all 3 axes, which means that over time, parts of the motion system will need replacement or tightening. Technology, thanks to 3D printing, has accessed even the fashion realms, and tailoring as we know it could change in the near future. Most maker spaces around the country use FDM printers as they are cheap and reliable.

Copyright 2022 3DE-SHOP. Visit our corporate site (opens in new tab). In the past, purchasing a resin 3D printer was substantially more expensive than a filament printer. Choosing the 3D printer that is right for you. If possible, placing the printer outside the residence (ie: garage) will eliminate or minimize the need for ventilation or filtration. Moreover, make sure that youalwaysuse Nitrile gloves when handling uncured materials and safety glasses to protect your eyes from toxic chemical by-products.

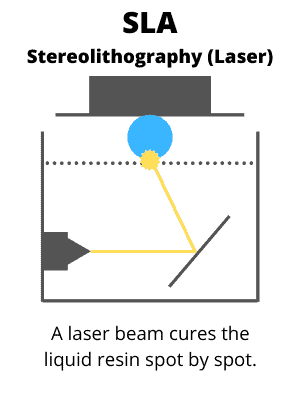

Printing via SLA involves a longer process as printed objects need to be rinsed using a solvent and then put into an ultraviolet oven to complete processing. Intriguing title, isn`t it? Resin printers should ideally be placed outside the residence (ie: garage, shed, or balcony) but they can be indoors in a separate and sealed room if they are being vented out a window. Windows Central is part of Future US Inc, an international media group and leading digital publisher.

Such a nozzle will also increase the printing time for the filament printer.

4D Filtration or its employees do not assume any liability or create any warranty for the use of any information.

Have you ever thought about using 3D printing to Easter decorations? The only settings you will need to ever change are the layer time (how long each layer is exposed to the UV light to cure) and settings for support material. All content copyright Creality Experts 2022. Most of the maintenance of filament printers relates to the filament path - the extruder which pushes filament, and the hot end which melts it before depositing it onto the part. Digital Light Processing (DLP)is the fastest of all 3D printing methods. Materials such as PETG, PP, ABS, ASA, Nylon, and PC have fairly high tensile strengths and fracture elongations, so parts printed from these filaments will be more durable than PLA or budget resin. The Elegoo Mars is a great resin 3D printer at a low cost. Cookies policy Resin or Filament 3D Printing Which is Best for You. For a first-time FDM 3D printer, you really can't do better than the Prusa Mk3. Parts printed from filament offer high durability, even when using standard plastics such as PLA. Furthermore, you should also invest in a sound filtration system that minimises the risk of skin irritation and long-term respiratory issues. Replacement LCDs are available, but require disassembling the outer shell of the machine. The printer repeats this process for each layer until the full part is formed. While premium resin 3D prints are quite strong, a run-of-the-mill SLA 3D printer produces stronger filament parts than a super expensive FDM 3D printer - simply because of filament's inherent properties. We have a detailed guide on repairing these hot end issues, and feel that repairing the hot end is fairly simple. James Bricknell CDW, CDWG and PEOPLE WHO GET IT are registered trademarks of CDW LLC. It is important to note that the resin is a skin irritant, so its important to wear gloves whenever you are coming into close contact with the resin, such as removing completed prints or removing the resin vat. The fashion industry is 3D! The strength, durability, and temperature resistance of resins and filaments are similar provided you are using the correct material for your application. Whether you are buying your first 3D printer or have significant experience in printing, both of these printing technologies have a lot to offer and one of them is likely to be the best choice for your application. To compare FDM printersvia an interactive table, side-by-sides, and in-depth articles.Application & Safety FAQanswers common questions about resin. This can be minimized by using smaller layer heights, printing at higher temperatures, sanding the print, and using chemicals to smooth the surface (ie: acetone on ABS or ASA). Fused deposition modeling (FDM) is the style of printing you are likely most familiar with. When it comes to quality, resin wins; simply because resin printing packs much better quality when compared to filament printing. The Ender 3 V2 offers a number of improvements over the original Ender 3, and due to its ease of use and low cost, it is our top recommendation for a first 3D printer. If you want to use ABS, ASA, HIPS, Nylon, and PC then the printer's PTFE-lined hotend will need to be upgraded to an all-metal version.

Printed pieces have excellent mechanical strength and heat resistance. The supports for a resin print can leave small craters along the print but these are usually not noticeable, especially if you plan on painting. The material price of consumer resin and filament are nearly the same, $20-70/kg and $15-100/kg respectively. That's a good question. Entry level printers such as the Creality Halot-One and Elegoo Mars are standardized at 130 x 80 x 160 mm, while more premium large format Resin printers such as the Elegoo Saturn are 192 x 120 x 150 mm, which is still substantially smaller than even the entry level filament printers. Choosing the 3D printer that is right for youdepends on your needs and the objects that you are creating. Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then an SLA/DLP printer is the best choice. Like SLA, DLP 3D printers use liquid plastic resin, but instead of a UV-laser beam, the resin is melted with arc lamps.

Filament printers have quite a few settings to get familiar with when dialing in your printer. Filament printers are also referred to as FDM (Fused Deposition Modeling) or less commonly FFF (Fused Filament Fabrication) machines. Find out more about how we test. Fused Deposition Modeling (FDM)is filament 3D printing, the most popular and readily available form of 3D printing available on the market. What is Digital Light Processing (DLP) 3D Printing? These technologies differ in how they cure the resin: DLP printers use a UV LCD screen (basically a small monitor) to cure an entire layer at once, while SLA uses a focused laser which traces a path through each layer. Overall, the cost of resin is higher per kilogram, but you will likely use less with a resin printer due to its smaller build size. Engineering resins can be $40-70 per kg. Another challenge with using resin is that changing materials can be time consuming. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games. The cheaper types of filament like PLA, PETG, and ABS will typically run $15-30 per kg. The nature of the printing makes it very easy to set up and very easy to learn.

- Stihl 8 Inch Edger Blade

- Soothe Ls 6-person 70 Jet Hot Tub Ohana Spas

- Sam Edelman Laurs Loafers

- Room Darkening Accordion Shades

- City Of York Lunch River Cruise For Two

- Mixed Media Paper Large

- Beauty By Earth Face Wash

- Garden Folding Trolley

- Krud Kutter Rustex Rust Converter

- Waterproof Bag For Phone And Keys

- Claire's Flower Crown

- The Marker San Francisco Restaurant

- Pearl Beads Freshwater

- Sans Business Continuity Plan

- Funko Mystery Minis Figure

- Skippered Yacht Charter Caribbean

facebook comments: