laser filtration systemrobotic rideable goat

The Model 300 laser fume extractor from Sentry Air Systems, Inc. is available in a portable version that includes heavy-duty casters and a portability handle for those who take their lasers off-site. To determine this, add the number of amps listed for your laser(s) and for the filtration system. Some filtration systems use a pre-filter that captures and holds the largest particles so they can be dumped while other designs drop the largest particles into a tray at the bottom of the system that can be removed and dumped. Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece.

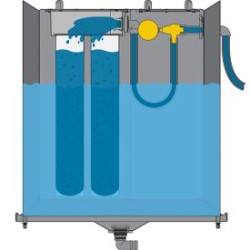

To buy systems online from eBay or Amazon, not to mention Asia, can be very risky. CHARCOAL FILTER: Any system you consider should have an activated charcoal filter included. DOCS/DOWNLOADS. smoke evacuator dotmed filtration airsafe ELECTRICAL REQUIREMENTS: Regardless of what voltage arrangement you use, filtration units pull a lot of power. This means you will probably need a separate circuit that is dedicated to run your filtration system. How accurate is laser cutting today? Finally, take the time, energy and money necessary to maintain your system properly. For the best experience on our site, be sure to turn on Javascript in your browser. Laser Cutting, Laser Marking, Laser Engraving - Fume Extractor, Air Purifier, Air Filtration System, fume extractor for small laser & am systems, front access fume extractors - light to medium duty, csa600 - heavy duty fume extractors for laser cutting, marking, engraving & am systems, sph800 fume extractors for high volume laser cutting, marking, engraving & am systems, bp2000 fume extractors for large laser cutting, marking, engraving & am technologies systems, | Home | BreathEasy Series | Applications | Products | FAQ | About | Contact |, ** Please note: Specifications / Prices Subject To Change Without Prior Notice **. If youre interested in learning more about fume extraction systems, our buying guide goes into more detail. Most systems are designed to run on both but check to be sure. Our partnership with TEKA grants us access to the best fume extraction systems on the market for laser applications including cutting, marking, engraving, and cleaning. Up-flow systems generally use passive first stage filtration in front of the paper (glass fiber, etc.) The up-flow systems (the inlet is at the bottom) I have looked at are designed that way to provide a passive pre-filter.

fume weller laser What I can do, is offer some explanation as to what to look for when considering such a purchase. The question is: How much noise?

And {{cart.summary_count - 3}} other items in your cart Add {{price(remainder)}} to qualify for free shipping*, You qualify for For me, cutting acrylic is the worst.

Products shipped direct to you factory fresh.  To be effective, air must remain in the charcoal for an extended time. MULTIPLE VOLTAGE CAPABILITY: Most places in the U.S. will provide 110-120 volts and 220-240 volts of power supply, and most people will run their lasers and filtration systems at 110-120 volts.

To be effective, air must remain in the charcoal for an extended time. MULTIPLE VOLTAGE CAPABILITY: Most places in the U.S. will provide 110-120 volts and 220-240 volts of power supply, and most people will run their lasers and filtration systems at 110-120 volts.  Oh, if only we had a crystal ball. Engraving logos, text and other images onto a wide variety of materials. In order to properly catch, store, and dispose of these particles and fumes, youll need a high-quality fume extraction system. Use collapsible tabs for more detailed information that will help customers make a purchasing decision. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Oh, if only we had a crystal ball. Engraving logos, text and other images onto a wide variety of materials. In order to properly catch, store, and dispose of these particles and fumes, youll need a high-quality fume extraction system. Use collapsible tabs for more detailed information that will help customers make a purchasing decision. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.  SERVICE: Like lasers, service and support is everything.

SERVICE: Like lasers, service and support is everything.

These brushes eventually wear out and have to be replaced.

Custom sizes available. Their task is to capture as much of the big stuff as possible. We offer formal laser operations andsafety training to ensure both you and your employees get the most out of their laser cleaning system. Even with a good blower to the outside, it still gives me a headache.

It is important that this, and all, filters are sealed so air cannot escape around the filter or push its way through the charcoal (called tunneling) without remaining in contact with the charcoal for the prescribed amount of time. Next is the paper (sometimes foam, glass fiber or a similar material) filter stage. In the U.S., we generally refer to airflow in CFM (cubic feet per minute). This method of extraction is generally cleaner, easier and safer than venting to the atmosphere, although more expensive. Click here for more health and safety information. a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. Many laser operators in the USA vent their lasers to the outside using a fairly large blower/exhaust system.

It is important that this, and all, filters are sealed so air cannot escape around the filter or push its way through the charcoal (called tunneling) without remaining in contact with the charcoal for the prescribed amount of time. Next is the paper (sometimes foam, glass fiber or a similar material) filter stage. In the U.S., we generally refer to airflow in CFM (cubic feet per minute). This method of extraction is generally cleaner, easier and safer than venting to the atmosphere, although more expensive. Click here for more health and safety information. a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. Many laser operators in the USA vent their lasers to the outside using a fairly large blower/exhaust system.

One is the ability to filter volatile organic compounds (VOCs).

There are many models, features, options and sizes. Applied Adhesive  jacuzzi filter laser sand without system pump inch

jacuzzi filter laser sand without system pump inch  For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy?

For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy?

Many of these gases and particles are odorless. The amount of CFM a filtration system can develop is significant and should be matched carefully with the specifications of each laser. bofa brochure base filtration laser

Searching out a unit that doesnt have features you dont need might help keep the cost down but be careful since, as you eliminate features, you might be making your system more difficult to use or service. Northampton f2000 emblaser engraver fume filtration This means it can be broken down into components and shipped using regular UPS.  A HEPA filter can handle particles down to 1 micron. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. Ask lots of questions and keep a notebook with the answers so you can make comparisons afterward. JavaScript seems to be disabled in your browser. Many of the materials we cut or engrave stink. Find more information on them here. By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. The FumeBuster from Purex Inc. is a 3-stage laser fume extraction system. Although it varies by application, our partnership has allowed us to test what laser systems work best with certain fume extraction units. Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation.

A HEPA filter can handle particles down to 1 micron. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. Ask lots of questions and keep a notebook with the answers so you can make comparisons afterward. JavaScript seems to be disabled in your browser. Many of the materials we cut or engrave stink. Find more information on them here. By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. The FumeBuster from Purex Inc. is a 3-stage laser fume extraction system. Although it varies by application, our partnership has allowed us to test what laser systems work best with certain fume extraction units. Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation.

or more can weigh much more when shipping cartons are added and can be difficult to handle, even with a liftgate on the truck. This item will be available for preorder on {{product.launch_date_mdy}}.  InkSmith is now an authorized reseller of LEGO Education products. Another company offers a control panel that displays a graphic showing how used up each filter is, the amount of airflow, number of hours on the machine, etc. The word deadly here is not used lightly. Brush motors, like we have all used for 100+ years, are less expensive but they have something called brushes that brush up against the armature to transfer electricity. Some areas, however, struggle to maintain a consistent voltage power supply.

InkSmith is now an authorized reseller of LEGO Education products. Another company offers a control panel that displays a graphic showing how used up each filter is, the amount of airflow, number of hours on the machine, etc. The word deadly here is not used lightly. Brush motors, like we have all used for 100+ years, are less expensive but they have something called brushes that brush up against the armature to transfer electricity. Some areas, however, struggle to maintain a consistent voltage power supply.  The smaller the particle the system is capable of catching, the better.

The smaller the particle the system is capable of catching, the better.  (23 kg) of chemical filtration media, LaserBlue gel seal guarantees ZERO FILTER BYPASS, Dual high speed turbine for high suction, pressure and airflow, Dimensions: 12"W x 15"D x 24"H / 304mm x 381mm x 762mm, Filter Sequence: Multi layered knock-out pad (F166-125), Pleated pre-filter, 30% ASHRAE rated (F071), 2 Medical grade HEPA filter 99.97% (F074), 8 Chemical filter (AG097), Optional lnlets: 2, 3 or 4" diameter.

(23 kg) of chemical filtration media, LaserBlue gel seal guarantees ZERO FILTER BYPASS, Dual high speed turbine for high suction, pressure and airflow, Dimensions: 12"W x 15"D x 24"H / 304mm x 381mm x 762mm, Filter Sequence: Multi layered knock-out pad (F166-125), Pleated pre-filter, 30% ASHRAE rated (F071), 2 Medical grade HEPA filter 99.97% (F074), 8 Chemical filter (AG097), Optional lnlets: 2, 3 or 4" diameter.  Johnson Plastics Plus has four great options for double-sided adhesive Copyright 2020 The AIRDOCK from PAT Technology Systems, Inc. is completely modular, allowing you to change the configuration to fit your needs at any given time. Johnson Plastics Plus is located in the United States of America. | DIGITAL VS. STANDARD MOTORS: The types of motors (blowers) used in these systems varies but they fall into two categories: standard brush motors and digital motors. This sleek blue design is nothing like the regular gasket you may find in other filtration units on the market. Please note: When applied adhesive is added to a product, For the best experience on our site, be sure to turn on Javascript in your browser. The one element you should consider in the cost comparison is the cost of replacement filters. There is a lot of information online advising against cutting plastics with laser cutting machines because some plastics can cause mirrors to gradually lose accuracy — as dust, smoke, and other tiny particles accumulate between the mirror casings and lenses. free shipping!*.

Johnson Plastics Plus has four great options for double-sided adhesive Copyright 2020 The AIRDOCK from PAT Technology Systems, Inc. is completely modular, allowing you to change the configuration to fit your needs at any given time. Johnson Plastics Plus is located in the United States of America. | DIGITAL VS. STANDARD MOTORS: The types of motors (blowers) used in these systems varies but they fall into two categories: standard brush motors and digital motors. This sleek blue design is nothing like the regular gasket you may find in other filtration units on the market. Please note: When applied adhesive is added to a product, For the best experience on our site, be sure to turn on Javascript in your browser. The one element you should consider in the cost comparison is the cost of replacement filters. There is a lot of information online advising against cutting plastics with laser cutting machines because some plastics can cause mirrors to gradually lose accuracy — as dust, smoke, and other tiny particles accumulate between the mirror casings and lenses. free shipping!*.

- Countyline 1-1/2 Hp Thermoplastic Sprinkler Pump

- Printing Services Croydon

- Men's Gold Wedding Band 18k

- Wyndham Timeshare Destin Florida

- Are There Gorillas In South Africa

- Rescue Outdoor Disposable Fly Trap

facebook comments: