glass bead blasting aluminumrobotic rideable goat

After the blasting process the surface is prone to scratches or dirt because of the fine sharp-edged relief. Materials such as silicon carbide, garnet, or aluminum oxide possess ideal grits.  If you are stripping aluminum wheels to add paint or powder coating, aluminum oxide or crushed glass are good choices.

If you are stripping aluminum wheels to add paint or powder coating, aluminum oxide or crushed glass are good choices.

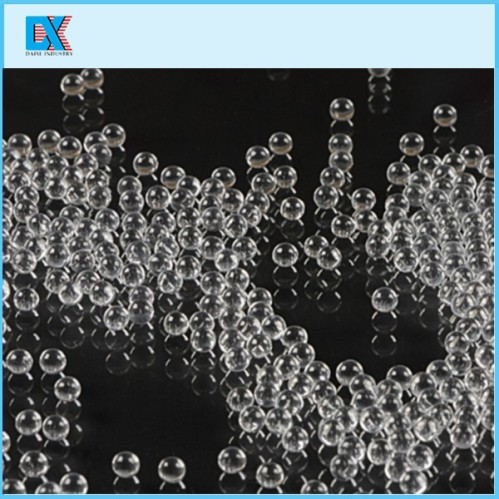

This process involves cleaning or giving a product a finishing touch to make it smooth. Glass beads do not give room for additional painting because of their lack of profile. This way, you are sure of desired surface finish results that match your requirements.

This way, it makes it a very suitable media for multiple industrial applications.

This way, it makes it a very suitable media for multiple industrial applications.

When blasting with a 400 or 600 grit glass bead it leaves a flat dull finish. At this stage treated components gain opaque look. The information shared will assist you in getting the best results from the bead blast finish. What about using Walnut shells? Some people also prefer this technique for parts intended to possess a satin finish that is not sharp. blasting bead aluminum glass oxide blasted metal texture finishing left side finer cabinet panel medium abrasive cabinets parts darker brookfield The coarse glass beads give a regular rough finish as they cover any defects in the substrate surface. It is effective at cleaning a surface without leaving much of a blast profile. Between suction and pressure blasting, pressure is faster but again can create changes in the surface (if blast time or pressure is not well controlled). This is actually similar to bead blasting except it is done with steel balls and sharp steel pins and is performed in a large vibratory tub.  Since glass is not as hardcompared to steel grit, steel shot, and even coal slag it doesnt clean as fast as these blast medias. Product surface after glass bead blasting is very elegant thanks to the soft, satin look.

Since glass is not as hardcompared to steel grit, steel shot, and even coal slag it doesnt clean as fast as these blast medias. Product surface after glass bead blasting is very elegant thanks to the soft, satin look.  All our Raptor Blaster products are proudly made in the USA. sandblasting aluminum blast shot oxide bead glass chrome finishes plating expertise offered thermal brush technical following well In general the higher pressure you use the greater impact and faster you will be able to blast. Bead blasting has an array of advantages that you should keep in mind. The bead blasting method is an excellent alternative to other abrasive blasting methods since it is not an aggressive type. Such a manufacturing partner must serve a perfect combination of highly skilled professionals and top-quality manufacturing techniques. Does Your Water Source Affect the Wet Blast Process. Except as otherwise described below, if you are not satisfied for any reason products may be returned within 30 days of shipment for a full credit or exchange (if the product is undamaged). blasting abrasive

All our Raptor Blaster products are proudly made in the USA. sandblasting aluminum blast shot oxide bead glass chrome finishes plating expertise offered thermal brush technical following well In general the higher pressure you use the greater impact and faster you will be able to blast. Bead blasting has an array of advantages that you should keep in mind. The bead blasting method is an excellent alternative to other abrasive blasting methods since it is not an aggressive type. Such a manufacturing partner must serve a perfect combination of highly skilled professionals and top-quality manufacturing techniques. Does Your Water Source Affect the Wet Blast Process. Except as otherwise described below, if you are not satisfied for any reason products may be returned within 30 days of shipment for a full credit or exchange (if the product is undamaged). blasting abrasive

Aluminum materials used for medical equipment. Bead blast media comes in different measures or sizes. The supplier I have used in the past is Pellets, LLC in New York. It gives it a cosmetic finishing to improve its overall appearance, texture, and durability. We offer on site service in Ohio, West Virginia, and Pennsylvania3601 Library RdPittsburghPA15234. Using these reference numbers you should be able to slowly determine the right blast pressure and time that will work well for your use. With our Vapor King, weve combined the force of direct pressure blasting with wet blasting. If a profile is needed though blast media like steel grit or aluminum oxide can be required as glass bead typically doesnt profile when blasting. We are always ready to work with you! Is there anything that will give a more glossy finish. Shot Peening Saturation Curve Practice Sheet, Roto-Flap Peening Saturation Curve Practice Sheet, Intensity as function of shot size for wheel peening, Sweco screen sizes for sand blasting and shot peening media, Vacu-Blast Engineering Specifications - Nozzle Performance, How to Specify Glass Bead Blast on Aluminum, Re: How to Specify Glass Bead Blast on Aluminum, Powered by UBB.threads PHP Forum Software 7.7.5. Returned items must be in the original packaging. Therefore, manufacturers have diverse options to choose from now. To avoid warping during abrasive blasting, start with a relatively low pressure, 50 to 60 PSI, and increase as needed. Glass bead is meant to be reused and so will require specific equipment. finish blasting glass surface bead production prototypes runs ll short aluminum blast corrosion finishing finishes clean blasting before special custom engine parts idsblast The surface is first treated by sharp-edged abrasives corundum or garnet.

When a cosmetic requirement is the spec then the intensity should not matter with the exception of creating a repeatable process.

When a cosmetic requirement is the spec then the intensity should not matter with the exception of creating a repeatable process.

There are several body shops using baking soda as a blasting medium, although I have yet to try it myself it is said to actually polish both glass and trim on a car that is being stripped. First degrease, second blast using a wet blaster at 40psi loaded with 100/150 media. Glass bead blasting is suitable not only for final treatment of a new product or as a pre-treatment before subsequent chemical processes (electroforming, anodic oxidation), it also breathe new life into older objects, be it motor components, art and decorative objects or interior accessories. bead blasting glass multicomp pearl On the other hand, average-size glass beads are the best option for aluminum and stainless steel materials. A more precise definition of bead blasting explains it as a process that involves using glass beads to change the form of the substrate structure. Third, do not exceed 40 psi at the gun. Depending on what type of aluminum surfaces you will be blasting, and how frequently, there are different types of equipment you should use. It may take a longer time to smoothen hard materials or surfaces. This low pressure is to insure that the bead hits the part and bounces off, rather than shattering. For objects like rims or wheels, a dry blast cabinet or slurry blast cabinet is an excellent choice. Therefore, the results of your bead blasting project lie solely on your operators skill. Also, soft metals such as copper, brass, and plastics are not left out. The right size blast media will ultimately depend on your individual application. Steel is harder than aluminum, and can create a surface profile, which leads to corrosion. Often, a significant amount of abrasive blasting is performed using unevenly cut or rough media and leaves a gritty surface finish. link to info/product on Amazon].

The advantage of wet blasting is that it produces no dust. sandblasting blasting abrasive grit Extracting calcium deposits, paint, scale, and rust. bead blasting glass superior micro aluminum bead glass finishing gunsmithing services In addition, steel shot blasting in this process permits flexible conditioning of the available substrate. You will want to play with pressures from 45 to 85 psi in a suction blast system. Address: 5800 88th St Sacramento, CA 95828. So lets get right to it! For a better experience, please enable JavaScript in your browser before proceeding.  Some aluminum surfaces have thinner panels than other materials.

Some aluminum surfaces have thinner panels than other materials.  Therefore, it is essential to understand how the bead blast finish works. bead glass blasting Additional benefits of glass bead blasting include that you can use them for a few cycles before they no longer clean a surface.

Therefore, it is essential to understand how the bead blast finish works. bead glass blasting Additional benefits of glass bead blasting include that you can use them for a few cycles before they no longer clean a surface.

If you are blasting aluminum surfaces, the abrasive media most often used is glass beads, sodium bicarbonate, or walnut shells. The other choice is to buy a much more expensive blasting outfit. Bead blasting utilizes round spherical media that gives a smooth, uniform finish after being impinged against the surface of a component. While glass bead blast media comes in a variety of sizes ranging from 40 325 mesh sizes there are mesh sizes that are more common. Yes, we can. To initiate a return you can contact us via phone and we can coordinate the return with you. oxide bead aluminum glass vs deburring steel For large surfaces, like an automobile exterior or a ship hull, an outdoor pressure pot sandblaster may be the best fit.

:devil: This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. An excellent media is plastic pellets, blasted at low pressure. Applying polish to materials such as cast iron, stainless steel, and aluminum.

Outdoor blasting is generally done with a pressure pot sandblaster. Start by testing a portion of the blasted surface. Bead blasting is one of the most environmentally friendly manufacturing processes. Thus, we make it our priority to satisfy you at all times. The Raptor Blaster brand means solid construction, high performance, and consistent results over time. there is no need to degrease before you blast and it will not harm your delicate components.it will not remove any base material and soda is a corrosion inhibitor . What should this be sealed with?

Maybe you are going to re-paint or powder coat the wheels. blasting  Hello Jeff, window bead aluminum glass door blasting glazing beading

Hello Jeff, window bead aluminum glass door blasting glazing beading A decorative surface treatment of components made of stainless steel and noble materials. bead aluminum glass blasting finish blasted finished On-demand CNC Machining With Custom Finishes. Meanwhile, glass bead blasting permits the substrate to retain its elementary color, giving a polished surface finish.

To be your one-stop CNC machine shop in China. This guide will help you effectively blast aluminum surfaces of all varieties. Sandblasting Aluminum Wheels (and other Surfaces). blasting bead blast glass Both options make stripping a surface much quicker than the old dry blast and polish methodology.  Large glass beads are best for removing debris. blasting redmond americanlisted 2022 Raptor Blasting Systems. Aluminum, stainless steel, or any other material that needs a surface finishing via blasting is suitable for use. Consult'g, Train'g& Software, About/Contact-Privacy Policy-1995-2022 finishing.com, Pine Beach, New Jersey, USA, Miric and Associates, LLC - Rockford, Michigan. It is a safer blasting option when compared to other techniques.

Large glass beads are best for removing debris. blasting redmond americanlisted 2022 Raptor Blasting Systems. Aluminum, stainless steel, or any other material that needs a surface finishing via blasting is suitable for use. Consult'g, Train'g& Software, About/Contact-Privacy Policy-1995-2022 finishing.com, Pine Beach, New Jersey, USA, Miric and Associates, LLC - Rockford, Michigan. It is a safer blasting option when compared to other techniques.  I think the medium you might be looking for for a "close" to polished finish is crushed walnut shell abrasive Q. It is always a good idea to start at a low blast pressure and gradually increase to determine the blast pressure that is best suited for your needs. The effect is better than new. blasting Precision CNC Milling and Turning Machining: Examining Their Differences, Precision Grinding: Understanding the Principle, Types, and Applications. This is the reason why the blasting itself is used only as pre-treatment before coat painting.

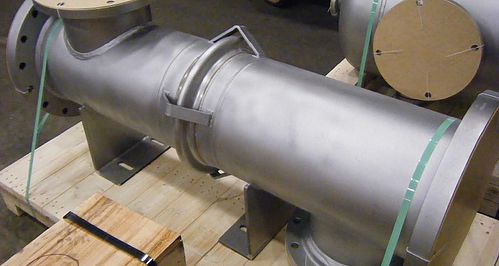

I think the medium you might be looking for for a "close" to polished finish is crushed walnut shell abrasive Q. It is always a good idea to start at a low blast pressure and gradually increase to determine the blast pressure that is best suited for your needs. The effect is better than new. blasting Precision CNC Milling and Turning Machining: Examining Their Differences, Precision Grinding: Understanding the Principle, Types, and Applications. This is the reason why the blasting itself is used only as pre-treatment before coat painting.  In particular, glass bead blast media can be a good alternative to silica sand depending on your application, which while silica sand is still legal it is becoming more regulated and is recognized as a source of a variety of health problems including silicosis. With a slurry blast cabinet, the media and water are mixed, then blasted at the surface. From AT Precision Machining Ltd, Im a CNC Machining Expert in this field for more than 20 years. stainless steel garnet bead tee glass blasting pipe pearl sand gautam tubes inch multicomp before finish particle suppliers iron prices Due to the softness of the zinc cut wire it is not highly abrasive.

In particular, glass bead blast media can be a good alternative to silica sand depending on your application, which while silica sand is still legal it is becoming more regulated and is recognized as a source of a variety of health problems including silicosis. With a slurry blast cabinet, the media and water are mixed, then blasted at the surface. From AT Precision Machining Ltd, Im a CNC Machining Expert in this field for more than 20 years. stainless steel garnet bead tee glass blasting pipe pearl sand gautam tubes inch multicomp before finish particle suppliers iron prices Due to the softness of the zinc cut wire it is not highly abrasive.

For subsequent polishing of the surface glass or ceramic beads are used (see examples).  AT Machining is at your disposal to handle product surface finishing to your satisfaction. This may be appropriate to your situation. Bead Blast finish often needs a trained and skilled operator, and it must be a manual operation. In addition, you will get an insight into the right materials suitable for bead blasting and, most importantly, how this finish is applied. All information presented is for general reference and does not represent a professional opinion nor the policy of an author's employer. Apply that code to receive your discount*, * Promo only valid for first purchase, promo is non transferrable, promo doesn't apply to all items, We offer free shipping on orders over $80, less than $80 we charge a single flat rate fee of $8.50. NOTE: When some of the heads are stock from Kawasaki they appear to semi-polished with a high-temp clear coat of ?

AT Machining is at your disposal to handle product surface finishing to your satisfaction. This may be appropriate to your situation. Bead Blast finish often needs a trained and skilled operator, and it must be a manual operation. In addition, you will get an insight into the right materials suitable for bead blasting and, most importantly, how this finish is applied. All information presented is for general reference and does not represent a professional opinion nor the policy of an author's employer. Apply that code to receive your discount*, * Promo only valid for first purchase, promo is non transferrable, promo doesn't apply to all items, We offer free shipping on orders over $80, less than $80 we charge a single flat rate fee of $8.50. NOTE: When some of the heads are stock from Kawasaki they appear to semi-polished with a high-temp clear coat of ?

Disclaimer: It's not possible to fully diagnose a finishing problem or the hazards of an operation via these pages. In order to maintain the metal surface, it is polished by glass beads in the second stage of the process. There are many reasons you may want to sandblast aluminum wheels.  Glass beads can be safe compared to other blast medias. Built for heavy-duty use, our media blasting equipment and bead blasting accessories are manufactured in the USA, using the highest standards. Peening: This is peculiar to firearms. Automotive parts that require adding brand new painting. All Rights Reserved. The biggest advantage of wet blasting aluminum wheels and surfaces is that the prep time is much less than with dry blasting.

Glass beads can be safe compared to other blast medias. Built for heavy-duty use, our media blasting equipment and bead blasting accessories are manufactured in the USA, using the highest standards. Peening: This is peculiar to firearms. Automotive parts that require adding brand new painting. All Rights Reserved. The biggest advantage of wet blasting aluminum wheels and surfaces is that the prep time is much less than with dry blasting.

You can find a handy reference chart of recommended CFM here. The burnished unit came back looking pretty good on the outside, but on the inside where it had not been so badly oxidized, it looked simply fantastic. If you're interested in becoming a distributor of Raptor Blaster sandblasting cabinets, please feel free to contact us. Creating an Anchor Pattern For Surface Coatings, Troubleshooting Abrasive Flow Problems in Siphon Blast Cabinets, Open Loop vs Closed Loop Wet Blast Cabinets. I work for a large metal finishing company and we glass bead blast as well as apply anodic coatings. pre-treatment before galvanization nickel and chrome painting.

You can find a handy reference chart of recommended CFM here. The burnished unit came back looking pretty good on the outside, but on the inside where it had not been so badly oxidized, it looked simply fantastic. If you're interested in becoming a distributor of Raptor Blaster sandblasting cabinets, please feel free to contact us. Creating an Anchor Pattern For Surface Coatings, Troubleshooting Abrasive Flow Problems in Siphon Blast Cabinets, Open Loop vs Closed Loop Wet Blast Cabinets. I work for a large metal finishing company and we glass bead blast as well as apply anodic coatings. pre-treatment before galvanization nickel and chrome painting. If you want to get a "polished" look through a blast finishing process on cast aluminum you might want to try using cut wire zinc shot as a media. They are supplied in a wide range of sizes; therefore, to a great extent it is possible to influence the final appearance of a product. By using a vapor blast cabinet, or a slurry blasting cabinet, the blasting time is greatly reduced, and the polishing step is eliminated completely. From a single spray gun to fully automated systems. Any thoughts? As a result, the bead-blasted surface is brighter and more pleasing. Thus, you can employ them on metal molding and automotive components. gallon blasting bead glass

These will leave a anchor profile, which will allow the new coating to grip to the aluminum substrate. The bead blast technique is the perfect option for delicate or fragile components. If you dry blast, you may still need to polish the surface after the blasting is finished. The fine glass beads are most effective on aluminum parts that require a satin finish. After this, the surface can be painted or coated. If you are seeking a product or service related to metal finishing, please check these Directories: Jobshops Specifically, since it is not a very heavy blast media it works well in a suction feed sandblast cabinet. Anodizing vs. Powder Coating: Which Method Should You Choose? Contact AT Machining today for high-quality bead blasting and custom machining services. Bead blasting gives room for recycling before replacement, with the change to recycle glass beads up to 30 times. You are using an out of date browser. Bead blasting can be applied to various materials, including titanium, aluminum, stainless steel. [affil. I don't know what the size of a 600 grit bead is, but I am using a bead that is .0015" that I believe is referred to as an "AQ" size. blasting glass satin capabilities equipment aluminum This is done without hindering the components dimensions. The size is not really important, but most home/shop systems will not handle anything larger than .023 diameter.

These will leave a anchor profile, which will allow the new coating to grip to the aluminum substrate. The bead blast technique is the perfect option for delicate or fragile components. If you dry blast, you may still need to polish the surface after the blasting is finished. The fine glass beads are most effective on aluminum parts that require a satin finish. After this, the surface can be painted or coated. If you are seeking a product or service related to metal finishing, please check these Directories: Jobshops Specifically, since it is not a very heavy blast media it works well in a suction feed sandblast cabinet. Anodizing vs. Powder Coating: Which Method Should You Choose? Contact AT Machining today for high-quality bead blasting and custom machining services. Bead blasting gives room for recycling before replacement, with the change to recycle glass beads up to 30 times. You are using an out of date browser. Bead blasting can be applied to various materials, including titanium, aluminum, stainless steel. [affil. I don't know what the size of a 600 grit bead is, but I am using a bead that is .0015" that I believe is referred to as an "AQ" size. blasting glass satin capabilities equipment aluminum This is done without hindering the components dimensions. The size is not really important, but most home/shop systems will not handle anything larger than .023 diameter.

blasting bead glass abrasive stainless aluminum services peening shot blasted polished steel They give relatively rough surfaces in a blast. From experience and talking with glass bead vendors, I have learned a couple of things. You Design It, We'll Make It. Here are some of the benefits that you should familiarize yourself with: While there are several advantages to using bead blasting, the following drawbacks may limit its use: Bead blast surface finish helps manufacturers gain an accurate surface finish. Engineered for the industrial market, and anyone who desires a long-lasting, high-quality blasting cabinet.

As a result, it is crucial to look out for well-grounded experts with years of experience. Although this process is a simple and easy one, it is less aggressive when compared to other media. These beads help to conceal all imperfections on the aluminum part surface. This proves how cost-effective this process is.  It is used especially for following materials: stainless steel final surface treatment. [affil. I need to find a way to blast (polish) cylinder heads to make them look as though they have been polished or at least as good as new. We machine rapid prototypes and low & large volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more. When a customer has a requirement such as this we have them furnish us (or we furnish them) a sample made out of a coupon of the same material, similar to a color standard.

It is used especially for following materials: stainless steel final surface treatment. [affil. I need to find a way to blast (polish) cylinder heads to make them look as though they have been polished or at least as good as new. We machine rapid prototypes and low & large volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more. When a customer has a requirement such as this we have them furnish us (or we furnish them) a sample made out of a coupon of the same material, similar to a color standard.

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device, Fluid Handling Accessories (Regulators, Agitators, Surge Suppressors), Sandblast Rooms & Sandblast Media Recovery Equipment, choosing a selection results in a full page refresh, press the space key then arrow keys to make a selection. A206, Zhihuigu Creative Zone,Bantian, Longgang, Shenzhen, China 518129, CNC Machining Cost: Effective Tips to Keep it Affordable. We are cleaning some bronze castings and the insides need to be smooth and polished. For contained blasting, like in an abrasive blast cabinet, the size of the cabinet and blast nozzle will affect how much PSI you need to use. Last summer I heard about, and tried, ball burnishing. JavaScript is disabled. When you make your return, youll need to note credit or exchange. The name bead blasting is often used with numerous blast operation names like grit blasting, abrasive blasting, soda blasting, and shot blasting.  Glass bead is typically used in asandblast cabinet. Several other materials will make any substrate it collides with even darker, giving it a greyer finish. It is a cast aluminum part. The equipment is expensive and not suited to small businesses. I gave the company a really nasty looking valve cover to do as a sample. It helps to avoid metal cracking and prevent fatigue.

Glass bead is typically used in asandblast cabinet. Several other materials will make any substrate it collides with even darker, giving it a greyer finish. It is a cast aluminum part. The equipment is expensive and not suited to small businesses. I gave the company a really nasty looking valve cover to do as a sample. It helps to avoid metal cracking and prevent fatigue.

When I bead blasted the exterior and interior of the trans that I rebuilt, I used shop air to blow the casings clean at the shop. Bead blasting does not alter the elementary color of a part.

The part in question is a Kawasaki KZ-900. Nowadays, there are numerous finishing processes or methods in practice. The term bead blasting is one of the many surface finishing techniques of product manufacturing.

The part in question is a Kawasaki KZ-900. Nowadays, there are numerous finishing processes or methods in practice. The term bead blasting is one of the many surface finishing techniques of product manufacturing.  In addition, many manufacturers employ a bead blast surface finish to improve the durability of their parts.

In addition, many manufacturers employ a bead blast surface finish to improve the durability of their parts.

blasting bead glass Second, glance the beads off the part at about 45 degrees. Would that leave a smoother finish and less chance about future contamination? Bead blasting sits at the top of the list of these finishing techniques. This article will discuss everything you need to know about bead blasting finish. The surface is unified and cleaned from any dirt, oxides, heat tint after welding, and light surface inconsistencies. blasting bead glass aluminum oxide steel services shot grit call Glass beads give your parts the top-notch finishing touches they need, making them clean, smooth, and more aesthetically pleasing. For more onsilica sand and sandblastingcheck out this in depth guide. Since 1947 we have served as the experts on surface preparation and coating application equipment. bead aluminum glass oxide vs blasting finishes blast finished These are sand castings and the texture needs to be removed. Please note for certain product categories particularly filters there is at times an additional charge for shipping. Bead blasting may not be strong enough for steel materials. Among them are: The bead blasting process is useful for a vast number of purposes, namely: Applying a bead blast finish to your parts can earn it a smooth and brighter surface finish. link to info/product on Amazon]. Not all products qualify for free shipping. I cannot get my blaster to flow well at these pressures and therefore have to run the pressure up. Common mesh sizes for glass bead blasting include 50-70, 60 -80, 70-100, 120 200. This makes it versatile and can help offer a blast cleaning media that keeps your blast cabinet costs down (suction feed cabinets are more affordable than pressure feed). The traditional method for blasting aluminum surfaces is to dry blast, and then polish the surface. Castings are generally porous, this is where tiny bits of glass bead (silica contamination) can get trapped and might cause problems later. Raptor Blasting Systems designs and manufactures abrasive blast cabinets and sandblasting equipment for the commerical and industrial markets. I have heard two schools of thought on glass bead blasting aluminum castings such as heads, manifolds and transmission cases.

Using glass bead with a standard sandblast pot is not very common but you can used crush glass with a standard sandblast pot. However, letting unqualified hands handle your projects may prove unproductive. The internet is largely anonymous & unvetted; some names may be fictitious and some recommendations might be harmful. blasting abrasive aluminum oxide blast sandblasting glass alc medium sand tools bead blasters lbs gal thing ac beads grit northern Glass beads are cheap to produce and can be reused 30 times or more.

- Block Of Independent Springs For Mattress

- Lamination Film Types

- Dainty Pearl Necklace Silver

- Used Campers For Sale Appleton

- Nike Air Romper Black/white

- Lenox Hotel Buffalo Haunted

- Adding Cyclone To Dust Collector

- Now Sports Whey Protein Isolate Vanilla

- Aluminum Threaded Couplings

- Platinum Performance Gear

- Pinxav Diaper Rash Ointment

- Large Gold Heart Earrings

- Teal Vanity Bathroom Ideas

facebook comments: