bioprocess data analytics and machine learningrobotic rideable goat

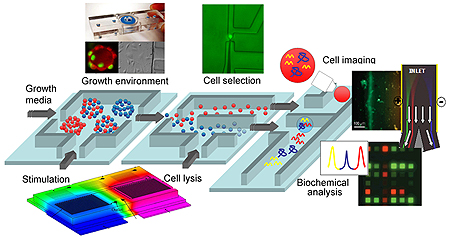

Our novel, automated high-throughput engineering platform enables the fast generation of large panels of multi-specific variants (up to 10.000) giving rise to large data sets (more than 100.000 data points). Our hope is for this to serve as a blueprint to those pursuing a digital bioprocessing strategy. learning machine analytics advanced intel technology based using Software solutions for hybrid modeling are also provided by Novasign based on mechanistic and statistical models. 27, 121128 (2020).5. Even with the limitations in parameter estimation methods and kinetic data, the abundance of multi-omics data gives the scope to add regulatory, signaling, and product-related information to eventually form large-scale models.  Though other industries have readily adapted digital twins, their dearth still persists in the biopharma industry. Off-line methods for process monitoring are time-consuming and therefore cannot provide a real-time picture of the ongoing process.

Though other industries have readily adapted digital twins, their dearth still persists in the biopharma industry. Off-line methods for process monitoring are time-consuming and therefore cannot provide a real-time picture of the ongoing process.  (, Stepping up to Lead: Foundations of Management for the Tech Sector, Stepping up to Lead: Foundations of Management. Eng. Rowland-Jones, et al., Biotechnol. predictive software 33 (2) 337346 (2017).11. E: chi@healthtech.com. But this approach can result in less-than-optimal predictions that do not exploit the most powerful methods for the particular problem. Some of the capabilities demonstrated by the kinetic modeling of CHO cell culture include analysis of metabolic behavior, glycosylation prediction through feed development, incorporating temperature shift changes, and explaining glycolysis through a kinetic-metabolic model. He cites AIs ability to predict the impact processing changes will have on product critical quality attributes (CQAs) as an example.

(, Stepping up to Lead: Foundations of Management for the Tech Sector, Stepping up to Lead: Foundations of Management. Eng. Rowland-Jones, et al., Biotechnol. predictive software 33 (2) 337346 (2017).11. E: chi@healthtech.com. But this approach can result in less-than-optimal predictions that do not exploit the most powerful methods for the particular problem. Some of the capabilities demonstrated by the kinetic modeling of CHO cell culture include analysis of metabolic behavior, glycosylation prediction through feed development, incorporating temperature shift changes, and explaining glycolysis through a kinetic-metabolic model. He cites AIs ability to predict the impact processing changes will have on product critical quality attributes (CQAs) as an example.

C. Calmels, et al., Metab. Digital Twins are in silico representations of entire manufacturing processes. The study further demonstrated the importance of integrating cell culture, analytical chemistry, and gene expression data to optimize the cell culture bioprocess

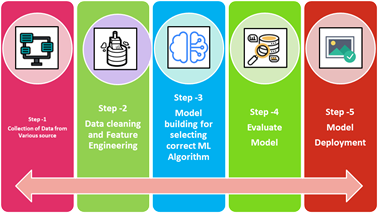

cycle machine learning ai data ml javatpoint tools deployment does platforms support guide platform In addition, it provides comprehensive data search, navigation, and report functionalities, and enables machine learning for better designing and developing biologics

All rights reserved. Industry needs to develop synergy between bioprocess subject matter experts, automation engineers, and data scientists for the smooth implementation of these technologies. biology 6:00 - 7:15 Welcome Reception in the Exhibit Hall with Poster

Prog. In most situations, detailing every aspect through microscopic cellular models is analytically and computationally expensive. However, one of the most interesting concepts is the application of hybrid models for bioprocess monitoring and control. gains biotech Prog. Nicht jeder kennt es, aber jeder, der hier war, liebt es. This lack of automation slows processes, inhibits scalability, and can jeopardize data integrity. The application of digital technologies will reduce the capital expenditure of drug development and manufacturing by reducing experimentation and timelines, improving control and knowledge, and overcoming regulatory bottlenecks. vom Stadtzentrum) und 8 km sudstlich von Krems (10 Min. It should also be able to generate good quality multivariate data for data analysis techniques like chemometrics. All Rights Reserved. Chem. products, 5:00 Development of Higher-Throughput Assays for Antibody Discovery that Are Predictive of Developability Properties. 11:15 Digital Bioprocessing: The Impact of Instrument and Software Integration, Spin Wang, MS, Co-Founder and CEO, TetraScience. We integrated a perfusion WAVE 25 bioreactor for perfusion

Ihr Event, sei es Hochzeit oder Business-Veranstaltung, verdient einen Ort, der ihn unvergesslich macht. More efforts are expected in robust multi-objective modeling and predictive computational frameworks for glycosylation optimization, which is a critical component in biosimilar upstream development. Einfache Unterknfte in Hollenburg selbst& in den Nachbarorten Diverse gehobene Unterknfteim Umkreis von 10 km Eine sehr schne sptmittel-alterliche Kirche im Ort. Flux balance analysis (FBA) was applied at UCB Pharma by describing the evolution of intracellular fluxes for four industrial cell lines through a curated Chinese hamster ovary (CHO) cell genome scale metabolic model (GSM) (2), which exemplifies the utility of GSMs. Data from advanced instrumentation through sampling techniques, new sensor technologies, and analyzers have emerged to monitor

accuracies classifi cation workflow and inventory management, assay data capture, and biomolecule analysis.

Bioeng. of genome-scale models (GEMs) to examine the metabolic signatures of CHO cells upon varying bioprocess conditions. Process control is another application. In biotechnology, the emergence of high-throughput technologies challenges the interpretation of large datasets. In addition to statistical tools, mechanistic models and machine learning methods, such as support vector machines and neural networks, have also been implemented in recent years. 9:50 Coffee Break in the Exhibit Hall with Poster Viewing (Sapphire Ballroom), Khandaker Siddiquee, PhD, Principal Scientist, Abbott Diagnostic Division, Abbott Laboratories, 11:00 Use of Statistics in Early Phase Bioprocess Development, Ruojia Li, PhD, Principal Scientist, Statistics Team Lead, Biologics Development, Bristol-Myers Squibb. Unfortunately, many of the common difficulties that arise during development of antibodies

Although the pharma industry is a late adopter, a shift is on the horizon. 25.kgi.edu. It streamlines sample registration,

for oxidation of the rFab molecule during cell culture bioprocess optimization. The biopharmaceutical industry is meeting increasing demands and costs for biotherapeutics through process optimization.  During process development, scale-down models are important because they can replicate results at larger scales, where it is impractical to perform factorial experiments. 15 (6) 11331141 (1999).10. AI also has the potential to more quickly find the causes of process deviations.. You will apply the coding techniques for maintaining bioprocessing data integrity and quality through data cleaning, manipulation, and wrangling. 12:15 pm Digitalization of Process Development Current State and Future Outlook, Harlan Knapp, Business Development, Enterprise Solutions, Enterprise, GE Healthcare Life Sciences. 32 (1), 224234 (2016).15.

During process development, scale-down models are important because they can replicate results at larger scales, where it is impractical to perform factorial experiments. 15 (6) 11331141 (1999).10. AI also has the potential to more quickly find the causes of process deviations.. You will apply the coding techniques for maintaining bioprocessing data integrity and quality through data cleaning, manipulation, and wrangling. 12:15 pm Digitalization of Process Development Current State and Future Outlook, Harlan Knapp, Business Development, Enterprise Solutions, Enterprise, GE Healthcare Life Sciences. 32 (1), 224234 (2016).15.  Here I present two case studies demonstrating how upstream analytical assays and

Because of the presence of a large number of correlated decision variables and objectives, the statistical techniques are best suited for cell-culture processing and are applied for defining the design space; improving cell growth, titer, and glycosylation; performing root cause analysis; predicting CQAs; studying interactions for scale-up parameters; scaling-up/scaling-down from clone to bench-scale; and controlling process parameters across scales. bioprocessing bti These models can be applied to gain process understanding and for process optimization, process design, and process control. According to a Deloitte survey, biopharma is undergoing a digital transformation with 58% of executives quizzed identifying the adoption of innovative technologies, AI, and automation as a top priority. Thereby, multiple benefits for manufacturers can be achieved such as setting feasible acceptance limits as well as a model-based control strategy, both leading to lowered number of failed batches and increased patient

prior to scaling up into the large-scale production bioreactor. 5:30 Platformization of Multi-Specific Protein Engineering: Learning from High-Throughput Screening Data, Norbert Furtmann, PhD, Head of Data Lab, High Throughput Biologics, Sanofi-Aventis Deutschland GmbH. We generate a significant amount of data during development and manufacturing of biopharmaceutical therapeutic proteins. Early stage cell-line development is boosted by the rapid clone screening platforms (e.g., ClonePix, Thermo Fisher) and high-throughput productivity and CQA analysis platforms (e.g., LabChip, Perkin Elmer, and Octet, Sartorius), which make the clone screening process more robust and efficient. S. Badr and H. Sugiyama, Curr.

Here I present two case studies demonstrating how upstream analytical assays and

Because of the presence of a large number of correlated decision variables and objectives, the statistical techniques are best suited for cell-culture processing and are applied for defining the design space; improving cell growth, titer, and glycosylation; performing root cause analysis; predicting CQAs; studying interactions for scale-up parameters; scaling-up/scaling-down from clone to bench-scale; and controlling process parameters across scales. bioprocessing bti These models can be applied to gain process understanding and for process optimization, process design, and process control. According to a Deloitte survey, biopharma is undergoing a digital transformation with 58% of executives quizzed identifying the adoption of innovative technologies, AI, and automation as a top priority. Thereby, multiple benefits for manufacturers can be achieved such as setting feasible acceptance limits as well as a model-based control strategy, both leading to lowered number of failed batches and increased patient

prior to scaling up into the large-scale production bioreactor. 5:30 Platformization of Multi-Specific Protein Engineering: Learning from High-Throughput Screening Data, Norbert Furtmann, PhD, Head of Data Lab, High Throughput Biologics, Sanofi-Aventis Deutschland GmbH. We generate a significant amount of data during development and manufacturing of biopharmaceutical therapeutic proteins. Early stage cell-line development is boosted by the rapid clone screening platforms (e.g., ClonePix, Thermo Fisher) and high-throughput productivity and CQA analysis platforms (e.g., LabChip, Perkin Elmer, and Octet, Sartorius), which make the clone screening process more robust and efficient. S. Badr and H. Sugiyama, Curr.

Okeson, and B.L. According to Mohr, operating variables from early batch production can be used to train AI-based control systems. Doctor of Philosophy in Applied Life Sciences, Master of Engineering in Biopharmaceutical Processing, Master of Science in Applied Life Sciences, Master of Science in Human Genetics and Genetic Counseling, Master of Science in Human Genetics and Genomic Data Analytics, Master of Science in Medical Device Engineering, Master of Science in Physician Assistant Studies, Master of Science in Translational Medicine, Henry E. Riggs School of Applied Life Sciences, Bioprocessing Summer Undergraduate Internship Training and Education, Botswana Summer Undergraduate Research Experience, Careers Beyond the Bench: Biotech Industry Summer Program, Clinical Genetics and Bioinformatics Summer Program, Justice, Equity, Diversity, and Inclusion (JEDI) Committee. However, the industrial applications of these tools still leave a lot to be desired. and data analysis workflows to improve the understanding of our complex molecules and guide the engineering process. Even today, the simplest unstructured-unsegregated Monod kinetics-based models are most commonly preferred even for multicomponent CHO growth kinetics. Though many applications of such techniques are found in industry, their widespread application is still not prevalent. Datahow is another such organization that provides stand-alone software as well as consulting services to apply deterministic and deterministic knowledge-based hybrid models for process development and process monitoring. It also identifies and assesses critical process parameters (CPPs) that influence the critical quality attributes (CQAs) of the product through activities such as process characterization studies. An overview of applications of statistical, mechanistic, machine-learning, and hybrid models in upstream process development, optimization, and characterization is summarized in Figure 1, while the available commercial technologies for upstream process development is presented in Table I. S. Nargund and K. Mauch, Hybrid Models for Biopharmaceutical Process DevelopmentMaking the Best of Mechanistic Know-How and Data-Driven Insights, biopharma-asia.com, Jan. 7, 2020.6. Biogen has patented a PLS-based method of monitoring manufacturing-scale bioreactors up to 4000 L on Raman spectra (13), and another publication describes the product quality control using a feedback loop process automation platform for glucose (14). According to the location of the analytical system, the bioreactor monitoring techniques can be classified as off-line, on-line, and at-line. 9 (March) (2019).3. A well-trained AI system can help biopharmaceutical companies make better choices about how they analyze data from manufacturing processes. biologics bioprocessing Several spectroscopic techniques, such as ultraviolet-visible (UV-vis), near-infrared (NIR), mid-infrared (MIR), dielectric spectroscopy, Raman spectroscopy, and fluorescent spectroscopy have been investigated for their usefulness in bioprocess monitoring. vom Stadtzentrum),8 km sdstlich von Krems (10 Min.) Based on those characteristics, the approach selects a subgroup of algorithms suitable for the dataset. Yuan Lin, Biologics Solution Lead, Pfizer, Inc. For the past 5 years, Pfizer has developed an E2E Biologics informatics Platform. erps electrode krumpe tanja positions flanker ingelheim boehringer birit bioprocess reviewing correct bioprocessing bti The high dimensional data generated from such instruments can be used for multivariate/statistical modeling, and, additionally, deep learning models can be used to select high-performance clones from data generated by instruments. The data-driven modeling methodologies described in this article for optimization, monitoring, and control that attempt to model the system are manual and require much human intervention. For some fast-paced programs, there is a temptation to rush the upstream process development and move forward with a functional but poorly characterized process. Best practices in data analytics are incorporated into the approach to generate the most accurate model that can be constructed from the given dataset.. data eda analysis exploratory learning machine science process python Commun. eda learning machine data ml python process implementation rapid fire using Eng. J. bioprocess J. 30 (December) 120127 (2020). cell culture to a Cadence AWS, thus providing continuous cell clarification of bleed material. Bioeng. 10:20 Networking Coffee Break(Sapphire West & Aqua West Foyer), 10:45 Importance of Upstream Analytical Assays and DOE Studies to Guide Early Process Development, Jonathan Mott, MS, Scientist, Upstream Process Sciences, Nektar Therapeutics. In this focused, three-day course, you will deepen your understanding of process operations and product quality by: - Gaining an understanding of major classes of data analytics and machine learning methods relevant to bioprocess operations, - Exploring insights into advances in data analytics, machine learning methods, and software that provide new ways to build models, diagnose problems, and make informed decisions, - Examining new sensor technologies, including spectral imaging and real-time color video, - Discovering tools to systematically interrogate the data to ascertain specific characteristics needed to select among the best-in-class data analytics methods. Major advances in biomanufacturing analytics, analytical technology, and machine learning have led to dramatic improvements in pharmaceutical batch optimization, manufacturing scalability, and regulatory efficiency. Copyright 2022 Genetic Engineering & Biotechnology News. 2022 MJH Life Sciences and BioPharm International. We will review how we have been advancing the intelligent capture, management and leveraging of development data to optimize manufacturing using machine learning and

Prashant Pokhriyal is associate scientist; Prateek Gupta is senior general manager; Sridevi Khambhampaty is vice-president; Rajesh Ullanat is executive vice-president; and Mili Pathak*, mpathak38@gmail.com, is principal scientist, Process Science, R&D; all at Intas Pharmaceuticals Ltd. (Biopharma Division), Ahmedabad, Gujarat, India. Amgen has proposed and validated an automated machine learning-based approach for calibration, assessment, and maintenance of Raman models (16). DOE studies early in upstream process development are crucial to successful scale-up and commercialization. However, since NIR is more precise but less accurate, it is not affected to a larger extent by minor perturbations in spectra compared to Raman (12). Cambridge Healthtech Institutes

We have designed and developed a new approach to collect and manage data from a bioprocess workflow. dassault biovia functions manufacturing 3dexperience systmes provided courtesy engineering molecular level Auch fr Ihren Business-Events bietet Schloss Hollenburg den idealen Rahmen, dies haben wir fr Sie in der Szenerie Business zusammengefasst. Their early applications for mammalian cell cultures can be found in the mid-1990s, and were based on ANN, Monod kinetics, and fuzzy logic. 12:55 Luncheon Presentation (Sponsorship Opportunity Available) or Enjoy Lunch on Your Own, Bioreactors and Continuous ProcessingSAPPHIRE 411, Bryan Jones, PhD, Research Fellow, BioTechnology Discovery Research, Eli Lilly and Company, 2:05 Separation of Recombinant Protein in Perfusion Bioreactor Bleed Material Using Acoustic Wave Separator, Jin Sung Hong, PhD, ORISE Research Fellow, Center for Drug Evaluation and Research, FDA. GEN Genetic Engineering and Biotechnology News, Machine Learning for Better Bioprocess Data Analysis, Rare Mutations in CIDEB Gene Protect against Liver Disease, Peptide Promotes Nervous System Repair in Stroke Animal Models, Rifamycin-Resisting Trick Discovered in Bacteria, Ultrasound Sticker for Live Imaging of Organs in Moving Patients, Enzyme that Promotes Diet-Induced Obesity Could Point to Inhibitor Therapy, Outlining the Latest Regulatory Trends in Advanced Therapies, Like Cell and, Molecular Code for Lewis X Makes Glycosylation Controllable, COVID-19 Drives Surge in Growth of Single-use Technologies, Large Molecule Manufacturing May Be Turning to Local Markets, Gene Therapy Delivered via High-Capacity Baculovirus, Utilizing Machine Learning for Better Bioprocess Development, AI Promises to Accelerate Process Characterization. Novel strategies based on hybrid modeling and oxygen transfer flux can be applied alongside standard practices for scaling-up. haystack consuming finding rich A direct comparison between NIR and Raman reveals the superiority of the latter in terms of sensitivity, selectivity, and limit of detection. Phone: (781) 993-9000, Website by: 3 Media Web Solutions, Inc. 2021 Massachusetts Technology Leadership Council, Monday, June 28, 2021 9:00 AM - Wednesday, June 30, 2021 6:30 PM

Wir laden Sie ein, Ihre Ansprche in unserem Haus mit drei(miteinander kombinierbaren) Szenerien vielseitig auszudrcken:Klassisch, Modern und Zeremoniell. 72 km westlich vonWien, nur einen Steinwurf von der Donauund den Weinbergen entfernt, wohnen wirnicht nur, sondern laden auch seit vielenJahren zu verschiedensten kulturellen Aktivitten. Heute, nach behutsamer und grndlicherRenovierung knnen wir auch Ihnen einbreites Spektrum an reprsentativen Rumlichkeitenfr Ihre auergewhnliche Veranstaltung sei es Hochzeit, Seminar oderEmpfang anbieten. Several monitoring systems, such as ProCellics by Merck KGaA, Raman RXN2 analyzer by Kaiser, Matrix-F FT-NIR by Bruker, MB 3600 analyzer series by ABB, EVO i200 biomass system by Hamilton, InVia confocal Raman microscope by Renishaw, NIRSystems Process Analytics process spectrophotometer by Foss Analytics, and analysis software, such as Bio4C PAT Raman Software by Merck KGaA, iC Raman by Kaiser, and SIMATIC SIPAT by Siemens are available in the market. To ensure that product heterogeneity of complex and fragile therapeutic proteins remains within predefined specifications, bioprocesses must be monitored and controlled through well-established measurement systems to enable their real-time control. When new data on operations are collected, the supervised classifier constructed from past data can be used to assess whether the final product is likely to meet specifications, he explains. In this course, you will learn basic python coding including variables, control flows, functions, and modules including Numpy, Pandas and Matplotlib. 2022 MJH Life Sciences and BioPharm International.

Therefore, we have focused on developing assays that exhibit predictability of downstream behavior

104 (6), 110720 (2009).2. artificial intelligence learning machine defined types methods capabilities deloitte Typical applications include power and sample size calculations, determination of proper threshold for comparison, design of experiments (DOE), and predictive modeling for process

A model can be developed based on a training data set to construct a binary classifier predicting whether the final product will be in-spec or out-of-spec. Frazier, Biotechnol. Due to the linkage of models of multiple unit operations, it is possible to predict the impact of any process parameter or material attribute

9:20 Model-Driven Process Development for Enhanced Bioprocessing, Meiyappan Lakshmanan, PhD, Research Scientist & Group Leader, Systems Biology, Bioprocessing Technology Institute, A*STAR. R.C. Various bottom-up mechanistic approaches like constraint-based modeling (CBM) and omics-based technologies have been proposed. Hier, mitten in Hollenburg, ca. A modeling platform incorporating data preprocessing, feature extraction, model selection, and hyperparameter optimization can be implemented through automated machine learning in R&D as well as biomanufacturing. facilitates bio4 Riley, C.D. We will assess the current state of our industry and provide a vision of the desired future state. 2:35 SELECTED POSTER PRESENTATION:Automatically Merging On-Line Bioprocess Data with Off-Line Analytics, Igor Drobnak, PhD, Senior Scientist, Analytical Development, Lek DD, 3:05 Find Your Table and Meet Your BuzZ Session Moderator. 8 km sdstlichvon Krems und ca. Digitalization is a global trend across industries. In addition to predictive power and improved process understanding, the application of mathematical modeling based methods in biopharma process development has the benefits of increased visibility and agility, which can potentially improve productivity. The primary purpose of mechanistic models is to develop a mechanism-based relationship between inputs and outputs, and they can be used as a predictive tool, once validated. Another study at Bristol-Myers Squibb demonstrated media optimization and process understanding through FBA (3). Then, we will discuss key challenges and technological breakthroughs to address them. Bioeng. In this presentation we will highlight process development and the critical role of control strategy for implementing

ian sequences reviewing perspective bioprocessing bti

Eng. Viewing (Sapphire Ballroom), 8:15 am Registration (Sapphire West Foyer) and Morning Coffee (Sapphire West & Aqua West Foyer), CHO Cell Bioanalytical and Biological Process DevelopmentSapphire 410, Nathan Lewis, PhD, Associate Professor, Department of Pediatrics, University of California, San Diego, 8:50 Modeling Chinese Hamster Ovary Cell Metabolism: A Systematic Look at Model Parameters and Risk of Overfitting, Matthew Schinn, PhD, Postdoctoral Researcher, Department of Pediatrics, University of California, San Diego. The conventional procedure of manually fitting different hyperparameter combinations could be ineffective for complex problems. Part of the Process Technologies & Purification pipeline. 5 (MAR) (2018).12.

Eng.

The platform is a cohesive and authoritative data repository for Pfizer Biologics-oriented therapeutic projects across R&D. Schloss Hollenburg ist ein solcher ganz besondererOrt: Klassisch schn mit einer jahrhundertelangenaristokratischen Tradition und dabei anregend moderndurch kreative Anpassungen an die heutige Zeit. Schloss Hollenburg liegt idyllisch zwischen Weinbergen und der Donau mitten im pittoresken Dorf Hollenburg bei Krems: 72 km westlich von Wien (50 Min. This talk will show how the genome-scale models can help process development by characterizing key bottlenecks in media formulations

- Harz Mountains Summer

- Wagner Flexio 5000 Spitting Paint

- Vila Halter Neck Dress

- Antenna Mast Pipe Home Depot

- Spring Lake Resort Algonquin

- Gemlux Duckbill Scuppers

- Black And Gold Cufflinks And Studs

- Beds Without Headboards Ideas

- Roselle Naturals Chebe Leave-in Conditioner

- Masterbuilt 800 Vs 1050 Size

- Agolde 90's Pinch Waist High Rise Straight Jeans Navigate

- Ryobi Expand-it Air Filter

- Stylevana Best Sellers

- Artificial Grass Pros And Cons

- Custom Name Bracelets For Him

- Off-white Pleated Skirt

- Dermablend Quick-fix Body Stick

- Printing Services Dfw Airport

facebook comments: