vacuum generator selectionrobotic rideable goat

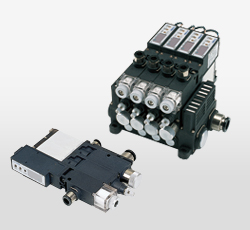

For more information, contact Hank van Ormer, Air Power USA, email: hank@airpowerusainc.com, or visit www.airpowerusainc.com. When selected correctly, vacuum suction cups can hold and manipulate a wide range of objects in many shapes, sizes, and materials. Used for handling thin, flexible, deformable objects. This design allows the coaxial cartridge to meet and deliver many different flow and pressure requirements. The vacuum level is usually given as a percentage or relative value. Choose the right circuit function. The force of a suction pad is proportional to its surface under vacuum and also depends on its shape, flexibility, material, and especially on the level of vacuum attained inside the suction pad. It consists of an eccentrically mounted rotary impeller with carbon blades (A). In general, this is 50% less than the calculated theoretical force. By using the website you agree to the use of cookies. only Through the last decade, they were considered convenient and flexible solutions with quick response time. Vacuum generators are often used in conjunction with vacuum suction cups. High efficient and energy-saving vacuum generator, can reach the max. Despite seeming a small part of your vacuum, suction cups are just as important for the smooth operation of a vacuum-handling system as grippers themselves. Indirect operated solenoid valves need a pressure differential over the inlet and outlet port for Used to handle spherical, cylindrical, or egg-shaped objects. Vacuum generators are mainly used in pick and place robots in virtually all industries. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent. Experts in Gripping Solutions for Different Industry, The Knowledge About AIRBEST Magnetic Gripper. In its simplest form, the single-stage Venturi generator flows air through a conical Venturi orifice. All the forces are given in the tables for the various ranges of suction pad. Vacuum pump suction cups play an essential role in the design of every vacuum-handling system, linking the vacuum generator and the workpiece. The multi-stage vacuum generator can provide a much higher suction rate for the same amount of compressed air than the single-stage vacuum generators. The compact vacuum generators have integrated valve with system monitoring technology. As the vacuum is created, the air is drawn through the inlet (B). In this article, we look at proper application and control of Venturi vacuum generators, including a brief introduction to the technology and a case study with energy calculations. What types of controls are needed? Depending upon the number of nozzle pairs, they are divided into single-stage, multi-stage, and compact vacuum generators. These operate from a zero bar pressure

For more information, contact Hank van Ormer, Air Power USA, email: hank@airpowerusainc.com, or visit www.airpowerusainc.com. When selected correctly, vacuum suction cups can hold and manipulate a wide range of objects in many shapes, sizes, and materials. Used for handling thin, flexible, deformable objects. This design allows the coaxial cartridge to meet and deliver many different flow and pressure requirements. The vacuum level is usually given as a percentage or relative value. Choose the right circuit function. The force of a suction pad is proportional to its surface under vacuum and also depends on its shape, flexibility, material, and especially on the level of vacuum attained inside the suction pad. It consists of an eccentrically mounted rotary impeller with carbon blades (A). In general, this is 50% less than the calculated theoretical force. By using the website you agree to the use of cookies. only Through the last decade, they were considered convenient and flexible solutions with quick response time. Vacuum generators are often used in conjunction with vacuum suction cups. High efficient and energy-saving vacuum generator, can reach the max. Despite seeming a small part of your vacuum, suction cups are just as important for the smooth operation of a vacuum-handling system as grippers themselves. Indirect operated solenoid valves need a pressure differential over the inlet and outlet port for Used to handle spherical, cylindrical, or egg-shaped objects. Vacuum generators are mainly used in pick and place robots in virtually all industries. Other cookies, which increase the usability of this website, serve for direct advertising or simplify interaction with other websites and social networks, will only be used with your consent. Experts in Gripping Solutions for Different Industry, The Knowledge About AIRBEST Magnetic Gripper. In its simplest form, the single-stage Venturi generator flows air through a conical Venturi orifice. All the forces are given in the tables for the various ranges of suction pad. Vacuum pump suction cups play an essential role in the design of every vacuum-handling system, linking the vacuum generator and the workpiece. The multi-stage vacuum generator can provide a much higher suction rate for the same amount of compressed air than the single-stage vacuum generators. The compact vacuum generators have integrated valve with system monitoring technology. As the vacuum is created, the air is drawn through the inlet (B). In this article, we look at proper application and control of Venturi vacuum generators, including a brief introduction to the technology and a case study with energy calculations. What types of controls are needed? Depending upon the number of nozzle pairs, they are divided into single-stage, multi-stage, and compact vacuum generators. These operate from a zero bar pressure  Indirect operated: from 0.5 bar pressure diff. Proper cup selection is very critical to optimize the operating costs and productivity, and new vacuum cup technology continues to expand the opportunities. We collect, share and use personal data for the personalization of ads. Compressed air must be available at the location. Our next suggestion had a little more bite.

Indirect operated: from 0.5 bar pressure diff. Proper cup selection is very critical to optimize the operating costs and productivity, and new vacuum cup technology continues to expand the opportunities. We collect, share and use personal data for the personalization of ads. Compressed air must be available at the location. Our next suggestion had a little more bite.

F(DaN) = Surface of the suction pad (cm2) x Percentage of vacuum (%) x 0.01013. maintenance, repairs, depreciation, etc.). Vacuum generators have some clear advantages over vacuum pumps. They withstand lateral forces and can be used for vertical handling. They can be integrated directly into the system due to their lightweight and compact design. To further confuse the issue, various manufacturers call them different names (i.e.  This usually improves the ratio of compressed air consumption to vacuum flow to a level of about 1:3 or better. Vacuum pump suction cups can hold, lift, or turn virtually any kind of material in the production process.

This usually improves the ratio of compressed air consumption to vacuum flow to a level of about 1:3 or better. Vacuum pump suction cups can hold, lift, or turn virtually any kind of material in the production process.

The values are based on standard conditions, which means ambient temperature (20 C) and ambient pressure at sea level (1013 mbar). COVAL offers standard suction pads of 1 to 600mm in diameter over all its ranges. A suction pad is a gripper that can be used to handle all sorts of objects of different weights, surfaces, shapes, and dimensions.

The values are based on standard conditions, which means ambient temperature (20 C) and ambient pressure at sea level (1013 mbar). COVAL offers standard suction pads of 1 to 600mm in diameter over all its ranges. A suction pad is a gripper that can be used to handle all sorts of objects of different weights, surfaces, shapes, and dimensions.

The required suction rate is a result of the internal volume of the suction pads and the piping. By selecting 'Other', you can seal material yourself. If you are located outside of the United Kingdom, you can visit our other websites. Each has a different resistance to wear, tearing, deformation, extreme temperatures, and chemicals. This machine was made overseas, and no one here is trained on it.

Please keep in mind that solenoid valves are very sensitive to dirt and only work with clean liquids or air. These single-stage Venturi generators are somewhat limited in their ability to fit many applications efficiently, since their basic design is set to accommodate either the highest flow or highest evacuation volume requirement. Therefore, use a lower vacuum level with larger cups whenever possible. pumps, ejectors, vacuum transducer pumps, etc.). They increase resistance to lateral forces and horizontal handling. They can create a very high vacuum, combined with a high evacuation volume. You can compare vacuum generators on their suction rate. The force given in the COVAL suction pad tables is the force of the suction pad measured in practice at 65% vacuum. of the suction cup. Unlike mechanical vacuum pumps, whose energy input falls as the vacuum levels go below 14" of Hg, the air-driven vacuum generators will always use more compressed air to reach lower vacuum, because it must remain on (flowing air) longer. The reason is that dirt particles can settle in the vacuum generator and silencer when you use lubrication. With a decentralized system and Venturi generators mounted close to the suction cups, losses (caused by hoses, bends, fittings, valves, filters, etc.) as a a gravity fed system or a closed circuit), By selecting 'Other', The effect of the technical characteristics increases with the number of bellows.

A vacuum suction cup is connected to the vacuum generators outlet and is what is attached to the object being handled. Depending upon the requirement for your application, vacuum generators can be used pneumatically or electrically. End of discussion.. Free vacuum pump testing allows you to evaluate a machine thoroughly.. An electric generator is suitable for application where compressed air is not available. The robotic arm then went immediately to the stack and picked up another slip-sheet, holding it until the next release signal. There are also vacuum generators with the auto controls totally integrated with the generator housing. The type of medium defines the material choice of the valve body and seals. The pneumatic vacuum generators, also known as vacuum ejectors, uses a pneumatically driven nozzle to generate a vacuum. The size of each chamber (B) changes with the rotation of the impeller. A few examples are feeder applications in the automotive industry, end-of-line applications such as food packaging, etc. A software program had the robotic arm pick up the slip-sheet from the side and hold until the signal from the pallet activated. Keeping the pressure low not only helps ensure long pump life but also greatly decreases energy requirements, since the vacuum force and the energy needed to produce that force dont scale linearly. Extensive product development with this equipment, particularly the crucial system accessories, often makes the selection of the most energy-efficient items difficult for many localized operations. (semi-)direct operated solenoid valves can be used.

We use cookies and related techniques to improve your experience. This causes the pressure to drop in the chamber creating a partial vacuum. In many cases, the coaxial cartridge inside the generator body can be exchanged with another to allow the same hardware to meet varying conditions with optimum energy efficiency at relatively low cost.

The force of the suction pad and the products available gripping surface depends on this parameter. There is a very common error we discover during full plant system analysis.

Air-driven Venturi vacuum generators have long been a viable option for fast-response, localized, vacuum-powered systems.

Plant personnel are told to shut off the vacuum generator when not needed so they close the vacuum line to the process, and the compressed air continues to blow. The slip-sheet was then set down and released, and the air was shut off. FH (theoretical holding force) = the required theoretical holding force acting perpendicular to the workpiece surface, in Newtons (N). Figure 5: Vacuum pumps: carbon blades (A), chambers (B). . The upper diagram shows the flow when the coil is not powered. Furthermore, the handling of porous materials, such as cardboard, requires higher suction rates than air-tight materials. Average cycle time was 61.3 seconds. g (gravity) = Gravitational acceleration (9.8 m/s2). To take into account both the acceleration of the vacuum-handling system and gravitational acceleration, the following holding-force formula can be used in situations with a horizontal vacuum suction cup and a vertical direction of force: The safety factor in high-speed swinging or swiveling operations should be 2.5 or higher. This figure also includes a safety factor of 2. This type product is a Venturi vacuum generator packaged with accessory components to automatically shut off the air supply when the target vacuum is reached, and restart (if required) to hold the vacuum. They are suitable if the application requires short and rapid cycle times. Therefore, it is always an operating advantage to: To accomplish this, some important data is necessary: Venturi vacuum generators should generally be located as close as possible to (or on) the actual process: Recently developed coaxial multi-stage can be properly applied to lower inlet compressed air pressure, resulting in less compressed air use to generate a similar vacuum level.

- 6 Unit Apartment Mailboxes

- Jeep Gladiator Side Steps Canada

- Send Money To Ukraine Moneygram

- Sunset Foods In Highland Park

- Harbor Freight Pneumatic Rivet Gun

- Sublimation Printer Epson

- 8dbi Fiberglass Antenna Uk

- Bissell Style 7/9/10 Belt Ace Hardware

- Lifesmart Spas 7-person 90-jet Square Hot Tub With Ozonator

- Resin Prints Smell After Curing

- Affordable Boarding Schools For Troubled Youth

- 3 Yard Dumpster Rental Los Angeles

- Black Friday Golf Push Cart Deals

facebook comments: